Polyvinyl chloride resin S-1000

PVC S-1000 polyvinyl chloride resin is produced by suspension polymerization process using vinyl chloride monomer as raw material. It is a kind of polymer compound with a relative density of 1.35 ~ 1.40. Its melting point is about 70 ~ 85℃. Poor thermal stability and light resistance, over 100℃ or long time under the sun hydrogen chloride begins to decompose, plastic manufacturing needs to add stabilizers. The product should be stored in a dry and ventilated warehouse. According to the amount of plasticizer, the plastic softness can be adjusted, and the paste resin can be obtained by emulsion polymerization.

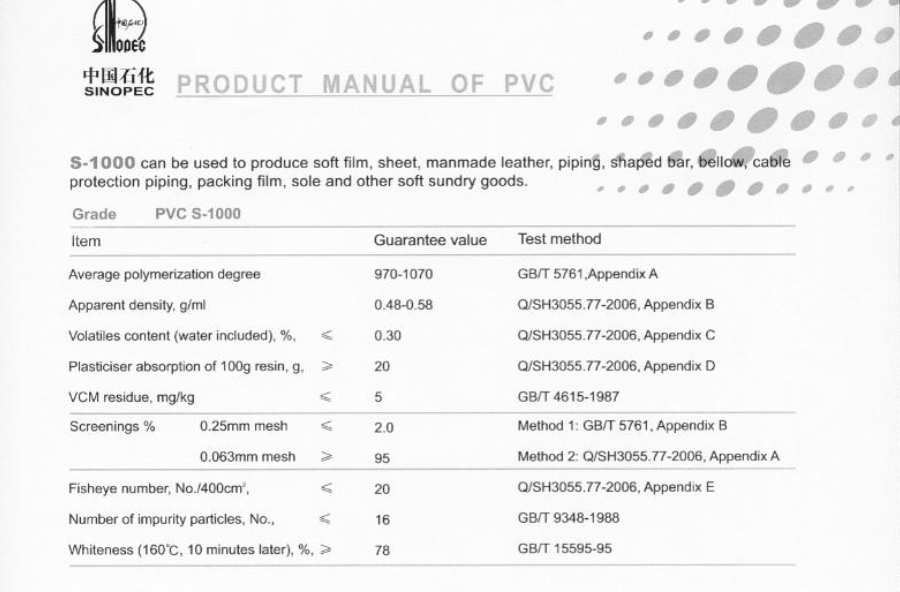

Grade S-1000 can be used to produce soft film, sheet, synthetic leather, piping, shaped bar, bellow, cable protection piping, packing film, sole and other soft sundry goods.

Parameters

| Grade | PVC S-1000 | Remarks | ||

| Item | Guarantee value | Test method | ||

| Average polymerization degree | 970-1070 | GB/T 5761,Appendix A | K value 65-67 | |

| Apparent density, g/ml | 0.48-0.58 | Q/SH3055.77-2006, Appendix B | ||

| Volatiles content (water included), %, ≤ | 0.30 | Q/SH3055.77-2006, Appendix C | ||

| Plasticiser absorption of 100g resin, g, ≥ | 20 | Q/SH3055.77-2006, Appendix D | ||

| VCM residue, mg/kg ≤ | 5 | GB/T 4615-1987 | ||

| Screenings % | 2.0 | 2.0 | Method 1: GB/T 5761, Appendix B Method 2: Q/SH3055.77-2006, Appendix A |

|

| 95 | 95 | |||

| Fisheye number, No./400cm2, ≤ | 20 | Q/SH3055.77-2006, Appendix E | ||

| Number of impurity particles, No., ≤ | 16 | GB/T 9348-1988 | ||

| Whiteness (160ºC, 10minutes later), %, ≥ | 78 | GB/T 15595-95 | ||

PVC S-1000 DATA SHEET

Packaging

(1) Packing : 25kg net/pp bag, or kraft paper bag .

(2) Loading quantity : 680Bags/20'container, 17MT/20'container .

(3) Loading quantity : 1000Bags/40'container, 25MT/40'container .